Heated Table ~ Part Four

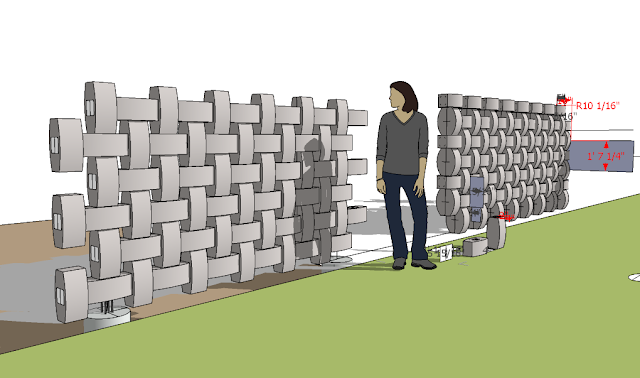

Okay, Here we go again. The last installment being back here. I've started doing some technical writing on how to construct a heated table frame near the end of this year. So far, this is what I've come up with:

The side pieces for the bottom are sized in the same manner, except they are positioned upside down in order to form a shelf with the simple addition of a ply-board cut to the finished perimeter. A height of six inches (or two circular holes spaces) is suggested.

Assembly manual for the heated table frame

Tools needed:

• A small adjustable wrench

• Fixed-size wrenches

• A 4-1/2” electric grinder ( or similar air-tool) with a cut-off wheel.

• A tape measure

• A small engineer’s square

• A pencil or scratch awl

(Front page)

This gauge of metal formed into ninety-degree angles can be purchased in the hardware department of home improvement stores in the USA

page1

The top pieces are sized so that the circular holes are 17/32” from their center to their ends, with mitre cuts of forty-five degrees on the top. The side pieces can be sized the same as the top pieces. Anything more than 23/32” from the centers to the ends will protrude above it.

page 2

The side pieces for the bottom are sized in the same manner, except they are positioned upside down in order to form a shelf with the simple addition of a ply-board cut to the finished perimeter. A height of six inches (or two circular holes spaces) is suggested.

page 3

Comments

Post a Comment