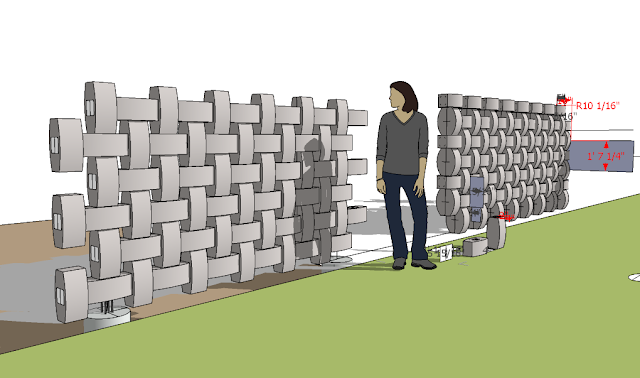

Free-standing Wall ~ Assembly Process

After getting a pretty good start a week ago work was done part time through the week in the evenings. The studs were cut to length and laid out. It being such a small a project the compressor and framing nail gun weren't needed.

The low ductwork came in handy in steadying the wall sections to bolt into the 2 x 6.

Just a couple "quick-grip clamps were needed to keep the bows straight during the fastening process.

The platform and side braces were a little tricky, but that was more due to the un-even floor in the basement. (At one time the author poured a self-leveling compound over it at the owner's request. Without a membrane re-inforcement stretched over it while still fresh it has started to blister and crack. The surface below, though primed to help adhesion was a sort of tar-mastic.)

The hardest part of the job would be getting it up to the fourth floor. The framework was hauled up the fire escape, and the sheetrock came in through the front entrance carefully up the stairway. The latter on a very windy March day typical to southern Colorado. One sheet was damaged in transit and the job would not be completed by end of Friday.

The client was not as suprised as the author by the size, but did have to perform some surprise re-arrangements in her work tables.

There is always a degree of excitement and re-freshening of purpose in preparing something new in a workspace. My client spoke of having a reticence about making dramatic changes, and wanting to combat it with this workstation. She spoke of wanting to jump right in with a new approach. I hope it serves her well. I'd make one for myself if I had the space.

The low ductwork came in handy in steadying the wall sections to bolt into the 2 x 6.

Just a couple "quick-grip clamps were needed to keep the bows straight during the fastening process.

The platform and side braces were a little tricky, but that was more due to the un-even floor in the basement. (At one time the author poured a self-leveling compound over it at the owner's request. Without a membrane re-inforcement stretched over it while still fresh it has started to blister and crack. The surface below, though primed to help adhesion was a sort of tar-mastic.)

The hardest part of the job would be getting it up to the fourth floor. The framework was hauled up the fire escape, and the sheetrock came in through the front entrance carefully up the stairway. The latter on a very windy March day typical to southern Colorado. One sheet was damaged in transit and the job would not be completed by end of Friday.

The client was not as suprised as the author by the size, but did have to perform some surprise re-arrangements in her work tables.

There is always a degree of excitement and re-freshening of purpose in preparing something new in a workspace. My client spoke of having a reticence about making dramatic changes, and wanting to combat it with this workstation. She spoke of wanting to jump right in with a new approach. I hope it serves her well. I'd make one for myself if I had the space.

Oh man, wish I knew how to actually make stuff. I consider myself "handy" because I know how to use a drill.

ReplyDeleteIf the apocalypse comes, I think you'll be in good shape!

Thanks! My physical limitations are getting such that I am forced to dip my toe into the information industry's pool and learn how to sell that, or go back to college and pick up where I left off over twenty years ago.

ReplyDeletePlease see my Virtual Sculpture blog listed in my links here.

Also, if you have any work you want to collaborate on, or have help in managing construction contractors (since I speak a lot of the lingo, and keep up to date on a lot of things in that regard) feel free to ask. I used to live in Austin, Texas, and still have friendly folks there I would love to visit with more often.